Conveyor Chain Applications

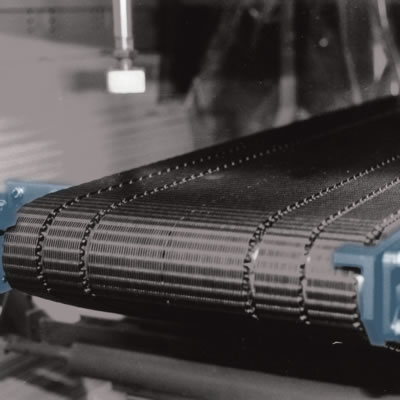

Inverted tooth conveyor chain technology is unsurpassed in terms of service life and availability. Renold has extensive experience in planning optimized transport solutions with inverted tooth chains. Economical and user-friendly solutions are two of our main priorities.

The use of inverted tooth chains in transport systems offers decisive advantages: Their lamellar structure makes them space-saving and variable in form and width. Plus, their low wear ensures high functional reliability with a long service life and they are especially resistant to extreme temperatures.

Transport and linkage system

For example, as linkage systems for flanges, camshafts, and for conveying sprockets

... for tool technology

- Low-vibration, smooth running

- High load capacity

- Low pre-tensioning

- Quiet operation

... for crankshafts

- High load capacity and narrow width

- Space-saving and variable in both form and width

- Smooth-running, no rocking of workpieces

... for cast housing

- Not susceptible to chips or coolant

- Long service life

- Robust design

Transport and storage systems

For example, for cast or aluminium housing, multi-track accumulators, for conveying in cycle and accumulation operation

... for flanges

- High resistance to wear

- Low elongation for secure positioning

- Extremely smooth operation

... adapted to minimal bearing surfaces

- Space-saving and variable in both form and width

- Low elongation for secure positioning

- Smooth-running, no rocking of workpieces

... for easily tipping transported

- Smooth running and even transport

- High resistance to wear

- High functional reliability

... for valve housing

- Space-saving and variable in both form and width

- Low elongation for secure positioning

- Smooth synchronized operation possible

Conveying heavy loads

For example, conveyor chains for the transport of assembly frames, in automobile assembly, as supply equipment for transmission components

... for assembly frames

- Low width despite heavy conveyed weight

- Compact, dense plate network (accident prevention)

- Even distribution of weight pressure – low surface pressure on the guide bed

- Smooth running for even driving

... in chassis dynamometers

- Larger widths also possible

- Compact, dense plate network (accident prevention)

- Uneven load bearing – here with direct contact between tires/vehicle and the tooth chain

... for conveyor sections in final assembly

- Ideally configured for maximum loads

- Highest degree of process reliability

- Automatic pulling along with electric overhead conveyors

- Assembly and maintenance without special aids

... for camshafts

- High load capacity and narrow width

- Minimal elongation, even with large conveying distances

- Simple shortening or repair possible

Special transport tasks

For example, inverted tooth chains with ground surfaces, inverted tooth conveyor chains with prisms, driver tooth chains for conveying car axles, driver tooth chains for pipe transport.

... with prisms for car axles

- High positioning accuracy

- Smooth-running, no rocking of workpieces

- Easy-to-mount plastic carriers

... with elevated special plates

- Integrated side guides for components

- Slip-smoothed plates for accumulation operation without workpiece abrasion

- Robust design without additional plastic workpieces

... as a subsurface tow chain

- Low width despite heavy conveyed weight

- Compact, dense plate network (accident prevention)

- Flexible design, e.g. with bushings for driving production carriers