Chain Drive Applications

Drive solutions with inverted tooth chains – as diverse as their applications!

Inverted tooth chains are used in a wide variety of applications and industries for classic circuit operation. Their technical features also make them ideal for reverse-operation drives.

The spectrum of possible applications for Renold inverted tooth chain ranges from drives with high speeds or exact positioning to drives with tangential meshing and heavy load applications, to special versions, for example corrosion-resistant variants for the food industry.

Inverted tooth chains for high speeds

For example for machine tools, textile machines, packaging machines, injection moulding machines, in rewinders or supply reels, for transmission test benches or other test benches

... for sprockets

- Low-vibration, smooth running

- High load capacity

- Low pre-tensioning

- Quiet operation

... for textile machines

- High load capacity

- Low wear due to elongation

- Extremely smooth operation

- High rigidity

... for separators

- Vertical positioning at vertical shafts

- High rigidity

- High load capacity

- Low wear due to elongation

... for chassis dynamometers

- Low wear due to elongation

- High efficiency

- For use with extremely variable speeds and loads

- No static pre-tensioning

Inverted tooth chain drives for precise positioning

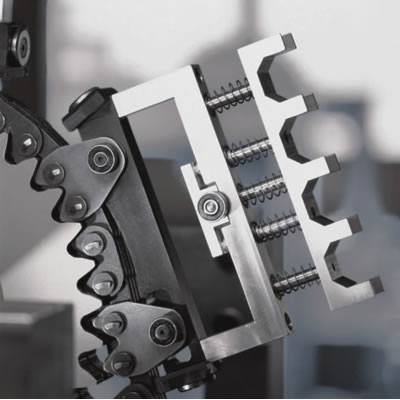

For example as tool changers, turnover stations, turning devices, feed drives, or a swivel drive in handling

... for tool changers

- Flexible mounting thanks to drivers

- Precise meshing conditions

- Low wear due to elongation

- High rigidity

... for turnover stations

- Minimum play

- Low wear due to elongation

- High rigidity

- Precise meshing

... for swivel arm drives

- Low-maintenance rolling pivot

- Low wear due to elongation

- High rigidity

- High repeatability

... for special grippers

- Low wear due to elongation

- High rigidity

- Minimum play

- Flexible design possibilities

Inverted tooth chains for drives with tangential meshing

For example as a swivel drive with gear rim, roller conveyor or roller drive, drum with gear rim, or rack drive

... as a toothed ring in diverse machines

- Easy transport/assembly in rolled-up state

- Low costs

- Integration via screws or welding

- Special plates with improved surface contact

... for roller drives in bonding systems

- Fewer drives

- Fewer idler sprockets as single drives

- Flexible power splitting

- Quiet operation

... for panel sizing saws

- Fewer drives

- Fewer idler sprockets as single drives

- Flexible power splitting

- Precise, play-free meshing

... as toothed ring segments in swivel devices

- Inexpensive segment solution

- Installation via end pieces for mounting, including chain tensioning

- Precise, low-vibration operation

Inverted tooth chains for drives in heavy load applications

For example as main spindle in drilling centers, drive for emergency pumping stations, main spindle operation in pipe finishing, draw bench chains, drive for roll coating, snow blowers, and wire-drawing machines

... for hot metal cars

- High operational reliability

- Long service life

- High load capacity

- Swivel and rotary operation in one

... for pipeline finishing machines

- High power transfer

- High operational reliability

- Long service life

- Smooth-running

... for roll grinding machines

- High power transfer

- Compact drives (small sprocket diameters possible with large width)

- High operational reliability

- Long service life

- Large gear ratios

... for batch tunnel washers

- High power transfer

- High operational reliability

- Long service life

- Reverse operation with unbalanced loads

Inverted tooth chain drive applications

For example as a drive for circuit board transport, in a linear block loader, with a corrosion-resistant version for food processing applications

... for pipe drawing machines

- Customer-specific versions with proven components

- High power transfer

- High operational reliability

- Long service life

... for extrusion presses

- Integration of drivers (e.g. loading bars) possible thanks to diverse plate forms

- High power transfer

- Flexible chain widths enable compact dimensions

... for example for handing units

- High rigidity

- Special plates to connect extra parts

- High operational reliability

- Low-play reverse operation

... for painting and dip tank systems

- Customer-specific versions with proven components

- High operational reliability

- Special plates to connect extra parts

- Low-play reverse operation