Tooth Chain Drive Product Overview

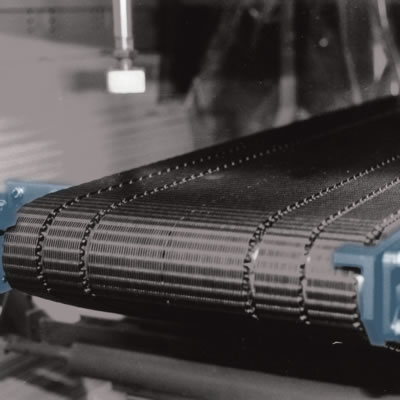

Our product range offers the right drive concept for every application and its specific requirements, including matching sprockets to ensure optimum functioning.

Advantages at a glance

- Industry-specific product innovations

- Components with needs-based additional equipment

- Customized overall solutions based on your specific requirements

- Long service life, easy assembly

Quality for every application

All Renold drive solutions feature extremely even, gentle, and precise running. With high-quality materials and production processes, our products can even be used in harsh environments, at high temperatures, or with aggressive agents.

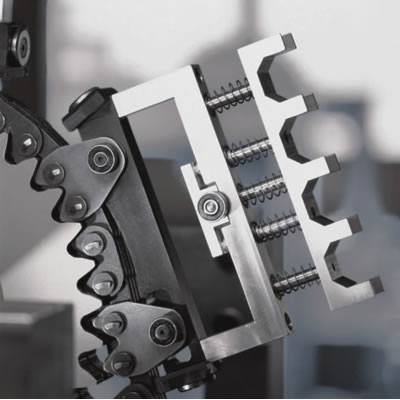

Inverted tooth chain types and special forms

HPC

State of the art. – The HPC, the most powerful type of Renold inverted tooth chains, sets new standards for wrap drives. Faster, quieter, and more precise than all other inverted tooth chains, it meets the highest demands.

Download HPC Datasheet >>

BIFLEX

The highest flexibility possible – symmetrically toothed link plates on both sides yield equal performance and precision during bilateral use. This makes BIFLEX the ideal solution for changes in direction of rotation or for multi-shaft drives.

Download Biflex Datasheet >>

Special forms

Individual – and always ready to meet your requirements. The maximum flexibility of the inverted tooth chain drive system allows it to be adapted easily to the most diverse requirements – from the individual special link plates to complete specialized inverted tooth chains, we have the right solution for your application!

HDL

Improvements to the link plate form and joint kinematics compared to the KH type help transfer larger forces within smaller spaces. HDL enables speeds up to 40 m/s.~

Download HDL Datasheet >>

KH

A tradition of quality – the KH inverted tooth chain was the first drive chain design to include a rolling pivot joint. This set the stage for the integration of inverted tooth chain drives in demanding applications. KH inverted tooth chains are still a safe and economical special solution for certain applications.

Download KH Datasheet >>